Concrete Sealing / Joint Sealing

Concrete Joint Sealing Services in TX, LA, and Nationwide

Concrete joint sealing is crucial for protecting concrete structures from water damage, cracking, and wear. For businesses, maintaining the integrity of concrete surfaces is vital, as it ensures the safety, durability, and longevity of their construction or remodeling projects. Proper sealing can prevent costly repairs and extend the lifespan of concrete installations. Ashton Sawing and Drilling offers expert concrete joint sealing services in TX, LA, and beyond, helping to ensure that surfaces remain pristine and structurally sound

Protecting Concrete Surfaces

Concrete is one of the most durable materials used in commercial and industrial infrastructure. However, without proper maintenance, even the toughest concrete surfaces can suffer from wear and damage over time. One of the best ways to protect your investment is through professional concrete joint sealing services. By sealing joints, we create a barrier against moisture penetration, which can cause water damage and lead to premature deterioration. This process helps in preventing cracks that may result from expansion and contraction due to temperature changes or heavy usage. Sealing protects against wear and tear, extending the life of the concrete while maintaining its appearance and structural integrity.

Preventing Wear and Tear

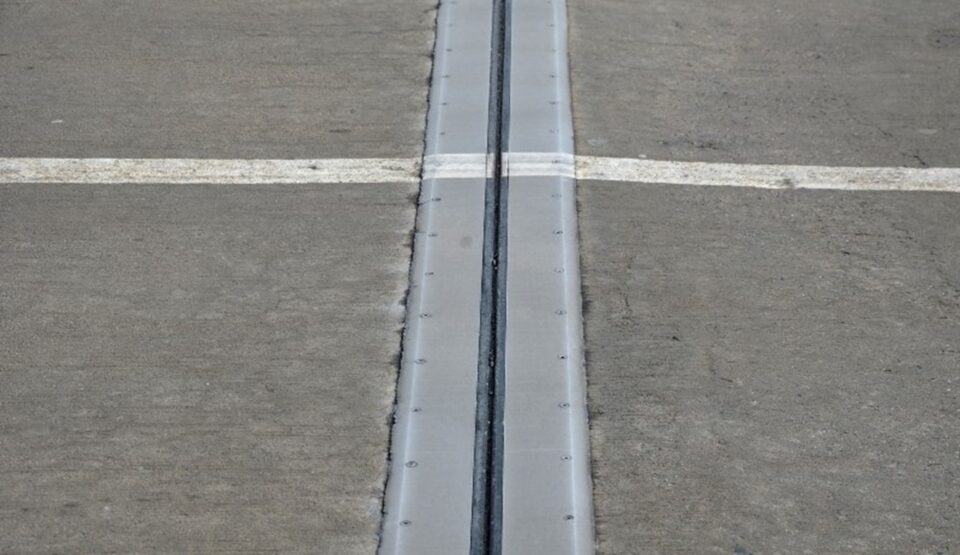

The joint sealing process involves filling and sealing the corners and seams in concrete to prevent water, debris, and other harmful substances from penetrating and causing damage. When left exposed, concrete can become prone to cracking, erosion, and even structural failure. Maintaining the integrity of concrete surfaces is especially important in commercial and industrial settings. These environments often experience heavy traffic, exposure to chemicals, and varying weather conditions, all of which can take a toll on concrete. Proper joint sealing helps to:

- Prevent Water Damage and Moisture Intrusion: Water is one of the most damaging elements for concrete. When it seeps into joints, it can cause freeze-thaw cycles, leading to cracking and spalling. Sealing the joints creates a barrier that keeps moisture out.

- Avoid Concrete Cracking and Wear: Unsealed joints allow debris and dirt to accumulate, which can act as abrasives and wear down the surface over time. This can lead to premature cracking and deterioration.

- Enhance Surface and Structural Longevity: By keeping harmful elements at bay, sealed joints help retain the structural integrity and appearance of concrete surfaces, ensuring they last longer and require less frequent repairs.

Our Joint Sealing Process

Because every project comes with its unique set of challenges, we provide tailored solutions that meet the specific needs of your commercial or industrial space. We take a comprehensive approach to joint sealing, ensuring that each step is executed with precision and care. Before we begin the process, our team conducts a thorough assessment of the concrete surfaces to identify any existing damage. We’ll determine the type and condition of the joints as well as any environmental factors that may affect the sealing process. Proper preparation is key to ensuring a successful and long-lasting seal.

Effective Materials and Techniques

Choosing the right sealing materials is crucial for achieving optimal results. We use high-quality sealants that are designed to withstand the specific conditions of your environment. Whether it’s a high-traffic commercial area or an industrial facility exposed to harsh chemicals, we work to find the best products for the job. Our experienced technicians apply the sealant with precision, ensuring that every joint is filled and sealed correctly. We pay close attention to detail, making sure that the sealant adheres properly and provides a durable, long-lasting barrier against moisture and other damaging elements.

Lock Out Moisture and Debris

Concrete joint sealing provides essential protection for structures, enhancing durability and preventing costly damages. Commercial and industrial projects can safeguard concrete surfaces from potential damage, ensuring long-term durability and cost-effective maintenance. Concrete sealing is essential for commercial industries because it protects critical infrastructure from water damage and prevents costly repairs. By sealing concrete surfaces, businesses can ensure durability, maintain structural integrity, and extend the lifespan of their investments.

Long-term Maintenance and Support

Concrete joint sealing is not a one-time task. Regular maintenance is essential to ensure the longevity and effectiveness of your sealed joints. At our company, we offer comprehensive maintenance services to keep your concrete surfaces in top condition, including regular inspections to identify potential issues early on for timely repairs. Our team provides expert recommendations to help extend the life of your sealed joints, offering tips on proper cleaning, usage guidelines, and best practices to keep your concrete surfaces looking and performing their best.

Protect Your Investment

Concrete joint sealing is an essential service for maintaining the integrity and longevity of your concrete surfaces. This process prevents water damage, reduces wear, and enhances the structural durability of concrete structures and surfaces. We are committed to providing comprehensive, high-quality services tailored to meet the unique demands of your commercial or industrial projects. With our dedication to customer satisfaction, we seek to provide the highest quality services. Contact us today to learn more about how concrete joint sealing can benefit your business.